The Latching Solenoid Valve provides a practical solution for systems that require low energy consumption. Unlike traditional solenoid valves that rely on continuous electrical current to hold their position, this type of valve uses a brief pulse to shift between open and closed states.

This operating principle offers significant energy savings. Once the valve changes position, no additional power is needed until the next activation. This is especially important in battery-powered applications, where extending battery life can help reduce maintenance and replacement costs.

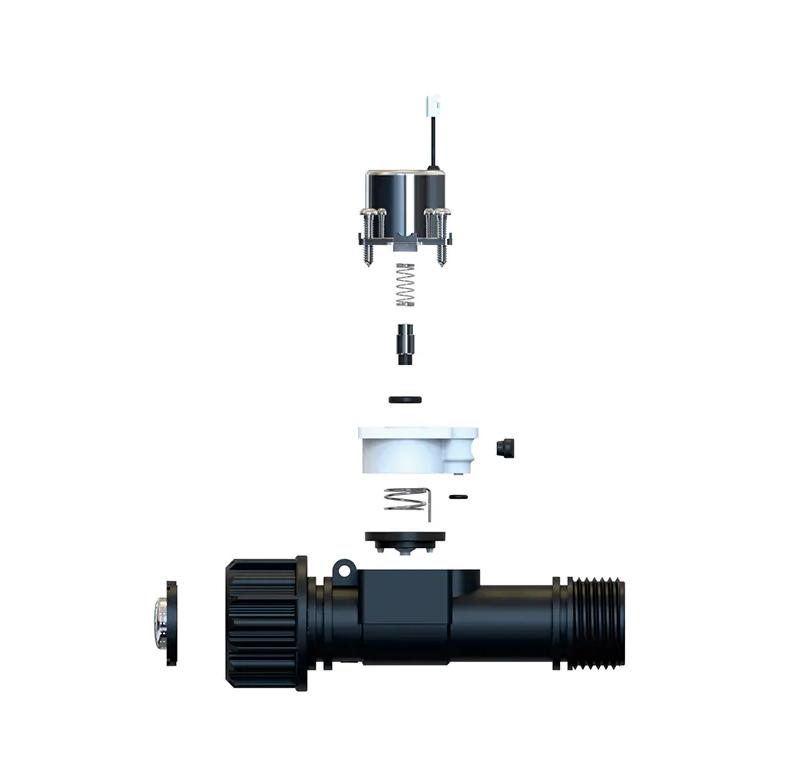

In irrigation systems, the Latching Solenoid Valve is often paired with controllers that deliver timed pulses. These controllers send a short signal to move the internal magnet, which latches the valve into the desired position. This design supports consistent operation without draining battery resources quickly.

Beyond irrigation, latching valves are used in water treatment, fluid distribution, and other applications that benefit from minimal standby power consumption. Their efficient design supports a variety of projects, including residential gardens, commercial landscaping, and agricultural fields.

Manufacturers typically build these valves with durable materials that resist wear and corrosion. Seals and diaphragms are selected for compatibility with treated water and common fertilizers, further enhancing long-term reliability.

Periodic inspection helps keep the valve operating properly. This includes checking electrical connections, verifying the sealing surfaces, and cleaning any filters that may trap debris. These steps help maintain smooth performance and consistent flow rates.

When designing systems where energy use is a concern, the Latching Solenoid Valve provides an effective way to manage fluid control without constant power draw. Its combination of low consumption, reliable switching, and compatibility with automated controllers makes it a strong option for modern water management.